CNC punching, also known as CNC punching machine, is a high-precision and efficient automated mechanical processing equipment, which is widely used and important in industry.

Firstly, CNC punchingcan automatically select suitable tools based on the set program to perform processing operations such as punching, tapping, indentation, drawing and cutting on metal sheets. This makes it widely used in many fields, such as automotive manufacturing, electronic equipment and communication, medical devices and biotechnology, aerospace and defense, as well as home appliances and office equipment. In these fields, CNC punching is used to manufacture various complex metal components to meet the specific needs of different industries.

Secondly, the high precision and high efficiency of CNC punching make it particularly suitable for situations that require large-scale mass production. By using CAD software, designs can be quickly iterated and modified, and high-quality products can be produced in a short period of time. This makes CNC punching one of the most advanced machining equipment in modern manufacturing.

In addition, CNC Punching can also be integrated with other advanced technologies, such as 3D printing technology, to provide more complex manufacturing solutions. This integration enables CNC punching to play a role in a wider range of fields, including shaping sturdy and lightweight special metals for aerospace components, and producing complex surgical tools.

CNC punching is widely used in the industrial field:

Electrical industry:

Distribution box and control cabinet: The side panels, door panels, and various installation plates of the cabinet body are manufactured through CNC stamping to ensure accurate punching and bending positions.

For example, in order to install electrical components, various specifications of installation holes need to be precisely punched on the side panel.

Instrumentation industry:

Instrument casing: Ensure the accuracy and protective performance of the casing.

The casing of high-precision measuring instruments usually requires CNC stamping to meet strict dimensional requirements.

Automotive components:

Radiator grille: Stamped with exquisite mesh shape.

Some high-end car radiator grilles showcase unique brand design styles through CNC stamping.

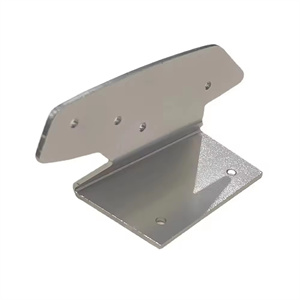

Small metal brackets and connectors: meet the requirements of lightweight and high strength for automobiles.

Metal product processing:

Nameplates and identification plates: Precisely stamped with text and patterns.

Nameplates on industrial equipment are usually stamped with CNC to ensure clarity and durability of identification.

In the electrical industry, Schneider’s distribution boxes extensively use CNC stamping technology to ensure product consistency and quality stability. In automobile manufacturing, BMW’s radiator grille has been improved in appearance quality through precise CNC stamping technology.