As a revolutionary manufacturing process, CNC punching has transformed the LED lighting industry, empowering us to produce high-quality, energy-efficient lighting solutions with unprecedented precision and efficiency. This advanced technology not only streamlines our production lines but also enables us to meet the ever-growing demands of the market, from residential to commercial applications. With its ability to handle a wide range of materials and create intricate designs, CNC punching has become an indispensable tool in our quest to illuminate the world with innovative LED lighting products.

1. Unleashing Efficiency with CNC Punching

In our LED lighting manufacturing operations, CNC punching has significantly enhanced our production efficiency. By automating the punching process, we can rapidly produce large quantities of components with consistent accuracy. Unlike traditional manual punching, which is time-consuming and prone to human error, CNC punching machines can execute complex patterns and designs with speed and precision. This automation allows us to reduce production lead times, increase output, and ultimately deliver our LED lighting products to customers more quickly. Whether we are manufacturing LED panels, fixtures, or other lighting components, CNC punching enables us to meet tight deadlines and maintain a competitive edge in the market.

2. Precision and Quality Assurance with CNC Punching

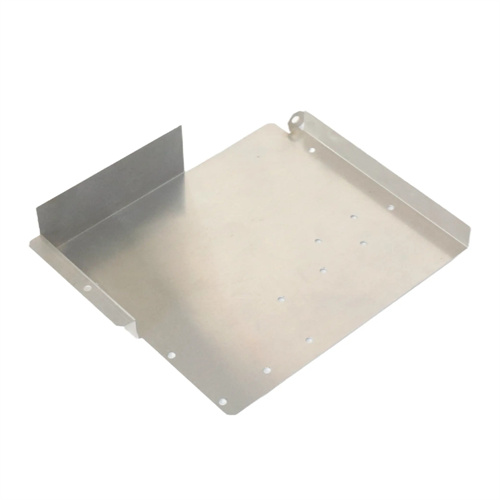

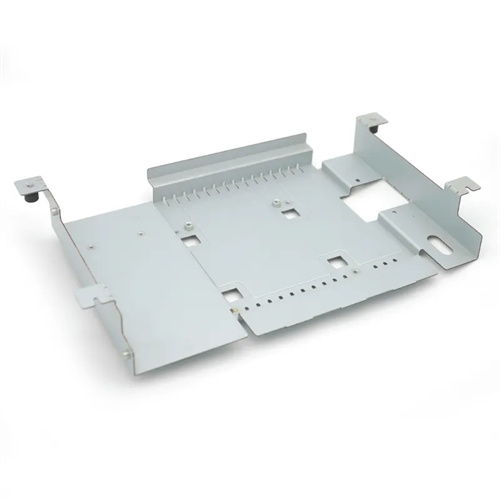

One of the key advantages of CNC punching in LED lighting production is its ability to ensure precision and quality. The advanced programming and control systems of CNC punching machines allow us to create components with exacting specifications, ensuring a perfect fit and optimal performance. We can precisely control the size, shape, and location of holes, slots, and other features, which is crucial for the assembly and functionality of LED lighting products. Additionally, CNC punching minimizes material waste by optimizing the layout of components on the sheet metal, reducing costs and environmental impact. By consistently delivering high-quality components, we can enhance the reliability and longevity of our LED lighting systems, providing our customers with products they can trust.

3. Design Flexibility Enabled by CNC Punching

CNC punching offers us unparalleled design flexibility in LED lighting manufacturing. With the ability to create intricate patterns and shapes, we can design unique and aesthetically appealing LED lighting products that stand out in the market. Whether we want to incorporate decorative elements, create custom light patterns, or optimize the heat dissipation of LED modules, CNC punching allows us to bring our creative visions to life. The use of computer-aided design (CAD) software enables us to quickly prototype and test different designs, making it easier to iterate and refine our products. This design flexibility not only allows us to meet the diverse needs and preferences of our customers but also gives us a competitive advantage in the highly competitive LED lighting industry.

4. Cost-Effectiveness of CNC Punching in LED Lighting

In addition to its efficiency and quality benefits, CNC punching also offers significant cost savings in LED lighting production. By automating the punching process, we can reduce labor costs and increase productivity. The precision of CNC punching minimizes the need for rework and scrap, further reducing costs. Moreover, the ability to optimize material usage through efficient nesting and layout planning helps us save on raw material costs. These cost savings enable us to offer our LED lighting products at competitive prices without compromising on quality. By leveraging the cost-effectiveness of CNC punching, we can increase our profit margins and invest in further research and development to drive innovation in the LED lighting industry.

5. Future Prospects of CNC Punching in LED Lighting

As the LED lighting industry continues to evolve, the role of CNC punching is set to become even more crucial. With the increasing demand for energy-efficient, intelligent, and sustainable lighting solutions, we will need to continuously innovate and improve our manufacturing processes. CNC punching will play a vital role in enabling us to produce more complex and advanced LED lighting products with higher precision and efficiency. Advancements in CNC punching technology, such as faster punching speeds, improved material handling capabilities, and integration with other manufacturing processes, will further enhance its capabilities and open up new possibilities for LED lighting design and production. We are excited about the future prospects of CNC punching in the LED lighting industry and look forward to leveraging this technology to create brighter, smarter, and more sustainable lighting solutions for the world.