OUR CAPABILITIES

High Speed Stamping

High speed stamping is generally used to produce hardware stamping parts with simple shapes, which are formed in one or two stamping processes. High speed stamping can produce one or two hundred pieces per minute, so large orders can be delivered in a short time.

Deep Drawing

The deep drawing of sheet metal parts is carried out through progressive or transfer molds, normally used in electrical appliances, various containers such as cans. the advantages of deep drawing parts are they can achieve a slender shape, wrinkle free and deformed surface.

CNC Punching

CNC Punching is often used to produce large hardware stamping parts, making stamping as simple as printing text on a printer through the free combination of mold blades. with the low mold costs, CNC Punching making stamping of large metal parts possible.

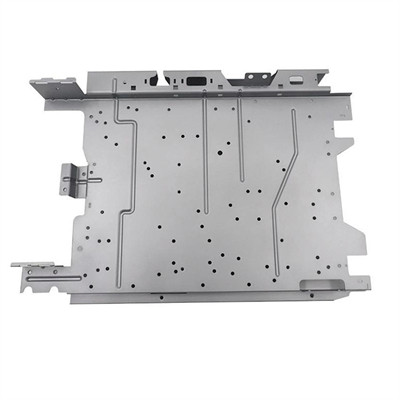

Sheet Metal Stamping

Sheet metal stamping is produced by CNC Punching machine combined with bending machine. has the advantages of light weight, high strength, conductivity (can be used for electromagnetic shielding), low cost, and easy mass production. It has been widely used in fields such as electronics, communication, and so on.

China Stamping Parts

The advantages of China Stamping Parts are the low cost of employees, factory buildings, and electricity bills in China. We have multiple machines that can minimize the cost of different stamping parts, such as using progressive punching for complex products, using fourslide or high-speed punching for simple products.

Springs

We also manufacture springs(compression springs, tension springs, torsion springs), CNC machining parts, and wire formed products, allowing our customers to achieve one-stop shopping and facilitate supplier management.