In the vast and dynamic construction industry, China stamping parts have emerged as an essential element, significantly contributing to the construction quality, efficiency, and cost – effectiveness of various projects. Leveraging advanced manufacturing technologies, rich production experience, and a strong commitment to quality, Chinese manufacturers produce a diverse range of stamping parts that meet the complex and demanding needs of the construction sector. From enhancing the structural stability of buildings to improving the functionality of interior and exterior components, China stamping parts play an indispensable role in our efforts to create durable, innovative, and sustainable construction solutions.

1. China Stamping Parts: Strengthening Structural Components of Buildings

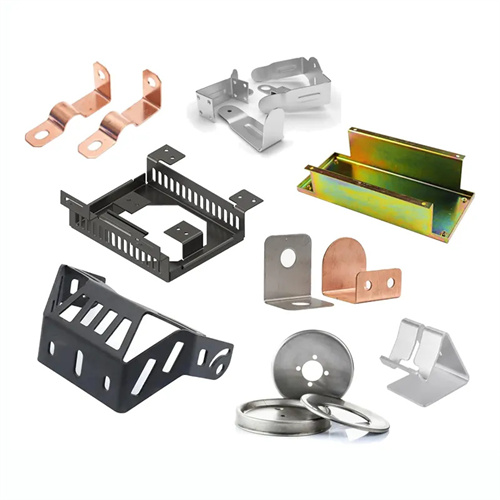

The structural integrity of a building is of utmost importance, and China stamping parts play a vital role in manufacturing key structural components. We utilize high – strength steel and other durable materials, processed through advanced stamping techniques, to produce components such as brackets, angles, and connectors. For example, in high – rise buildings, China – made stamping parts are used to create steel brackets that reinforce the connections between beams and columns. The precision of the stamping process ensures accurate hole positions and shapes, enabling seamless assembly and enhancing the overall stability of the building structure. These stamping parts can withstand heavy loads and various environmental stresses, providing reliable support for the entire building, thus safeguarding the safety of occupants and ensuring the long – term durability of the structure.

2. China Stamping Parts: Fabricating Metal Roofing and Siding Panels

Metal roofing and siding panels are widely used in modern construction for their durability, aesthetics, and energy – efficiency. China stamping parts enable us to produce high – quality metal panels with precise dimensions and attractive designs. By stamping metal sheets, such as aluminum and galvanized steel, we can create panels with smooth surfaces, uniform profiles, and accurate interlocking mechanisms. In industrial buildings and commercial complexes, China – made stamping parts are used to manufacture metal roofing panels that offer excellent weather resistance and water – tightness. The stamping process also allows for the creation of various textures and colors, enhancing the visual appeal of the buildings. Additionally, the lightweight yet sturdy nature of these stamping – made panels reduces the construction load and simplifies the installation process, contributing to cost – savings and increased construction efficiency.

3. China Stamping Parts: Creating Decorative Metal Elements for Architectural Aesthetics

In the pursuit of unique and aesthetically pleasing architectural designs, China stamping parts are used to create a variety of decorative metal elements. We can stamp metal sheets into intricate patterns, shapes, and profiles to add artistic touches to buildings. For instance, in historical restorations or luxury commercial buildings, China – made stamping parts are used to produce ornate metal railings, grilles, and facade decorations. The precision of the stamping process allows for the reproduction of detailed designs, from classic motifs to modern geometric patterns. These decorative metal elements not only enhance the visual charm of the buildings but also showcase the craftsmanship and cultural heritage. Moreover, the use of corrosion – resistant materials in stamping ensures the long – lasting beauty and functionality of these decorative components.

4. China Stamping Parts: Manufacturing HVAC and Plumbing Components

Heating, ventilation, and air – conditioning (HVAC) systems as well as plumbing systems in buildings rely on a range of components, and China stamping parts are essential for their production. We stamp metal sheets into various shapes to create components such as duct connectors, pipe brackets, and ventilation grilles. In large – scale commercial buildings, China – made stamping parts are used to produce duct connectors that ensure a secure and air – tight connection between ventilation ducts, improving the efficiency of the HVAC system. For plumbing applications, stamping parts are used to fabricate pipe brackets that provide stable support for pipes, preventing sagging and leaks. The accuracy and consistency of China stamping parts in manufacturing these components ensure the proper installation and reliable operation of building systems, contributing to the comfort and functionality of the indoor environment.

5. China Stamping Parts: Facilitating Cost – Effective and Sustainable Construction

China stamping parts offer significant advantages in terms of cost – effectiveness and sustainability in the construction industry. With advanced automated stamping equipment and efficient production processes, we can produce large quantities of stamping parts in a short time while maintaining strict quality control. This high – volume production reduces the cost per unit, making construction projects more economically viable. Additionally, many of the materials used in China stamping parts, such as steel and aluminum, are highly recyclable, promoting sustainable construction practices. By using China stamping parts, we can minimize material waste, reduce environmental impact, and achieve cost – savings without sacrificing the quality and performance of construction projects. This combination of cost – effectiveness and sustainability makes China stamping parts an ideal choice for the modern construction industry.