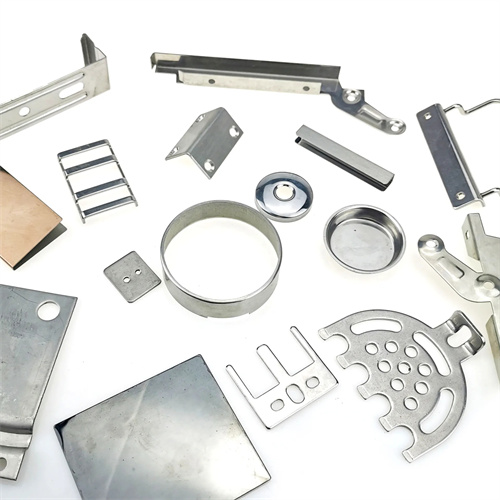

In the ever – evolving and highly demanding field of electrical products, China stamping parts have emerged as a cornerstone of manufacturing, significantly enhancing the quality, functionality, and competitiveness of a wide range of electrical devices. Leveraging cutting – edge manufacturing technologies, strict quality management systems, and cost – effective production capabilities, Chinese manufacturers produce stamping parts that meet the diverse and exacting requirements of the electrical industry. From robust enclosures and efficient heat – dissipating components to precise connectors and structural supports, China stamping parts play a crucial role in our pursuit of creating reliable, innovative, and high – performing electrical products.

1. China Stamping Parts: Fabricating Durable Electrical Enclosures

Electrical enclosures are essential for protecting internal components from external factors such as dust, moisture, and physical damage, and China stamping parts are key to manufacturing top – notch enclosures. We utilize high – quality metal sheets, like stainless steel and galvanized steel, and advanced stamping techniques to create enclosures with precise dimensions and tight tolerances. For example, in power distribution cabinets, China – made stamping parts are used to form enclosures that provide excellent protection against environmental hazards. The stamping process allows for the creation of smooth surfaces, seamless joints, and accurately positioned cutouts for wiring and component installation. Additionally, features such as ventilation holes and cable glands can be incorporated during stamping, enhancing the functionality of the enclosures. These durable enclosures, enabled by China stamping parts, ensure the safety and reliability of electrical products, even in harsh operating environments.

2. China Stamping Parts: Manufacturing High – Efficiency Heat – Dissipating Components

Effective heat dissipation is crucial for the optimal performance and longevity of electrical components, especially in high – power electrical products, and China stamping parts excel in this area. We can stamp heat sinks and heat – dissipating plates from materials with high thermal conductivity, such as aluminum and copper, into complex shapes with optimized fin designs. In servers and power supplies, China – made stamping parts are used to produce heat sinks with precisely spaced fins, maximizing the surface area for efficient heat transfer. The precision of the stamping process ensures consistent fin thickness and spacing, which improves the overall thermal performance of the heat – dissipating components. By using these high – quality stamping parts, we can keep electrical components at safe operating temperatures, reducing the risk of overheating and component failure, and thus enhancing the reliability and lifespan of electrical products.

3. China Stamping Parts: Crafting Precise Electrical Connectors and Terminals

Electrical connectors and terminals are critical components that ensure reliable electrical connections within electrical products, and China stamping parts enable us to produce these with high precision. We stamp connectors and terminals from conductive metals like brass and copper, shaping them into various forms to meet different connection requirements. For instance, in printed circuit boards (PCBs), China – made stamping parts are used to create pins and sockets that provide secure and stable connections for components, ensuring the smooth flow of electrical signals. The tight tolerances achieved through stamping guarantee proper mating of connectors, reducing the risk of loose connections that could lead to electrical failures or intermittent operation. Moreover, surface treatments like plating can be added during the stamping process to enhance the conductivity and corrosion resistance of these components, further improving their performance and durability.

4. China Stamping Parts: Creating Structural Supports for Electrical Devices

Inside electrical devices, structural supports are necessary to hold various parts in place and provide stability, and China stamping parts offer excellent solutions for this. We can stamp brackets, frames, and mounting components from strong and lightweight metals, such as aluminum alloy, to support heavy electrical components like transformers and motors. The precise hole locations and dimensions of these stamping parts ensure easy installation and alignment, facilitating the assembly process. In electrical cabinets and control panels, China – made stamping parts are used to create mounting rails and brackets, allowing for flexible arrangement of electrical components, optimizing space utilization, and improving accessibility for maintenance. The strength and durability of these stamping – made structural supports ensure that they can withstand the mechanical stresses and vibrations associated with the operation of electrical products, maintaining the integrity of the overall system.

5. China Stamping Parts: Facilitating Cost – Effective and High – Quality Production

One of the significant advantages of China stamping parts in the electrical product industry is their ability to enable cost – effective and high – quality production. With automated stamping presses and progressive dies, we can produce large quantities of stamping parts in a short time while maintaining strict quality standards. The standardized production process reduces labor costs and minimizes material waste, as the metal sheets are efficiently utilized during stamping. This cost – effectiveness is particularly beneficial for high – volume electrical product manufacturing, such as consumer electronics and household appliances. At the same time, Chinese manufacturers’ commitment to quality control ensures that each stamping part meets the required specifications, providing reliable components for electrical products. By leveraging China stamping parts, we can offer electrical products that are both cost – competitive and of high quality, meeting the demands of a global market.