In the robust and competitive realm of hardware tool manufacturing, sheet metal stamping has emerged as an indispensable and transformative technique for us. As we strive to produce high – quality, durable, and efficient hardware tools that meet the diverse needs of professionals and DIY enthusiasts, sheet metal stamping offers a wealth of benefits. It enables us to create precise components, streamline production processes, and optimize costs, all while maintaining strict quality standards. From wrenches and pliers to complex power tool components, sheet metal stamping plays a pivotal role in shaping the hardware tools that are essential for various construction, repair, and maintenance tasks.

1. Precision – engineered Components by Sheet Metal Stamping in Hardware Tools

Sheet metal stamping empowers us to fabricate precision – engineered components that form the core of reliable hardware tools. When manufacturing wrenches, for instance, sheet metal stamping is used to create the jaws with exacting tolerances. The advanced die – making technology combined with high – speed stamping presses allows us to achieve precise shapes and dimensions, ensuring a snug fit on nuts and bolts of different sizes. This precision not only enhances the functionality of the wrench but also minimizes the risk of slippage during use, providing users with a safer and more efficient tool. Similarly, in the production of pliers, sheet metal stamping helps us form the handles and gripping mechanisms with high accuracy, enabling comfortable handling and a firm grip on various objects. These precisely stamped components are the key to delivering hardware tools that perform consistently and meet the high – standards of our customers.

2. Enhancing Production Efficiency with Sheet Metal Stamping in Hardware Tool Manufacturing

Efficiency is crucial in the hardware tool industry, where meeting high market demands requires rapid production processes. Sheet metal stamping offers us a significant advantage by enabling high – volume and continuous manufacturing. High – speed sheet metal stamping machines can operate at extremely fast cycles, producing hundreds of components per minute. When manufacturing large batches of nails or screws, we can use sheet metal stamping to quickly form the heads and shafts in a seamless process. This high – volume production capability allows us to fulfill large orders promptly, reducing lead times and ensuring a steady supply of products to the market. Moreover, the automated nature of sheet metal stamping reduces the need for extensive manual labor, minimizing human errors and further boosting the overall production efficiency of our manufacturing operations.

3. Cost – effective Solutions Enabled by Sheet Metal Stamping in Hardware Tool Production

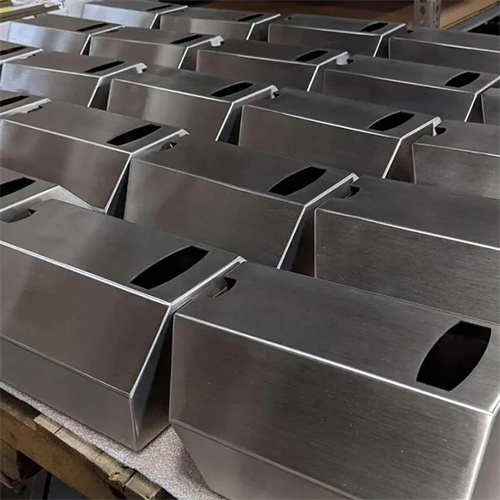

Cost control is a vital aspect of hardware tool manufacturing, and sheet metal stamping provides us with effective cost – saving strategies. Although the initial investment in sheet metal stamping equipment and dies can be substantial, the long – term benefits far outweigh the costs. The high production speed and efficiency of sheet metal stamping reduce the cost per unit of components. By producing components in large quantities, we can take advantage of economies of scale, spreading the fixed costs over a greater number of units. For example, when manufacturing metal toolboxes, sheet metal stamping can produce the panels and frames at a lower cost compared to traditional fabrication methods. Additionally, the optimized use of materials in sheet metal stamping minimizes waste, as the metal sheets can be nested and cut with precision to maximize material utilization. This efficient use of resources, combined with reduced labor costs due to automation, makes sheet metal stamping an economically viable option for our hardware tool production, allowing us to offer competitive prices without compromising on quality.

4. Material Adaptability in Sheet Metal Stamping for Hardware Tool Components

The hardware tool industry requires the use of diverse materials to meet different performance and durability requirements, and sheet metal stamping offers us the flexibility to work with a wide range of materials. We can utilize materials such as carbon steel, stainless steel, and alloy steel, each with its own unique properties. Carbon steel is often chosen for its high strength and affordability, making it suitable for tools that require robust construction, such as hammers and axes. Stainless steel, on the other hand, is preferred for its excellent corrosion resistance, making it ideal for tools used in harsh environments or for food – related applications. Alloy steel combines the advantages of multiple metals, offering enhanced strength, hardness, and wear resistance. Sheet metal stamping can handle these different materials effectively. By adjusting the stamping parameters and die designs according to the material’s characteristics, we can ensure that the components are formed accurately and retain their desired mechanical properties, enhancing the performance and lifespan of the hardware tools.

5. Quality Assurance in Hardware Tool Production via Sheet Metal Stamping

Maintaining high – quality standards is non – negotiable in the hardware tool industry, and sheet metal stamping plays a crucial role in quality assurance. Advanced monitoring systems are integrated into sheet metal stamping equipment to continuously monitor the production process. Sensors can detect variations in parameters such as stamping force, die temperature, and component dimensions in real – time. If any deviation from the set standards is detected, the system can immediately trigger alarms, allowing us to take corrective actions promptly. Regular maintenance of the stamping equipment and dies also ensures consistent performance. Additionally, strict quality control checks are carried out at various stages of the sheet metal stamping process, from material inspection to the final assembly of components. This comprehensive quality assurance approach guarantees that the hardware tools we produce meet or exceed industry standards, providing users with reliable and long – lasting tools that they can trust for their projects.