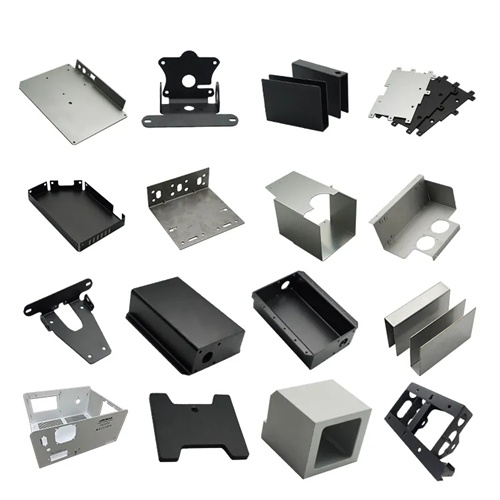

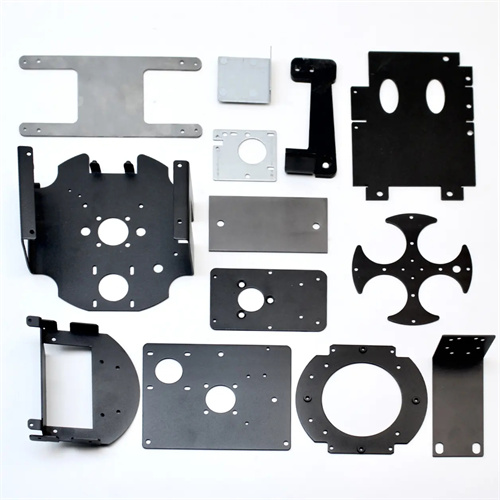

In the dynamic landscape of household appliance manufacturing, we have harnessed the capabilities of CNC Punching to revolutionize our production processes and elevate the quality of our products. This advanced technology has become an indispensable asset, enabling us to craft components with precision, speed, and flexibility. From refrigerators and washing machines to microwave ovens and air conditioners, CNC Punching plays a crucial role in shaping the parts that ensure the functionality, durability, and aesthetic appeal of these everyday appliances. By integrating CNC Punching into our operations, we not only meet the demands of a competitive market but also drive innovation in the industry.

1. Accelerating Production with CNC Punching

CNC Punching has significantly accelerated our production cycles in household appliance manufacturing. In the past, traditional punching methods were labor-intensive and time-consuming, often leading to delays in meeting market demands. However, with the introduction of CNC Punching machines, we have automated the punching process, enabling us to produce a large number of components in a fraction of the time. These machines can execute complex punching patterns at high speeds, with the ability to switch between different designs seamlessly. For example, when manufacturing the metal frames for washing machines, CNC Punching allows us to produce multiple units simultaneously, reducing production lead times and increasing overall output. This increased efficiency not only helps us respond quickly to market fluctuations but also allows us to scale up production to meet growing consumer needs.

2. Ensuring Precision and Quality in Components with CNC Punching

Precision is key in household appliance manufacturing, and CNC Punching has been instrumental in helping us achieve the highest levels of accuracy in component production. The advanced control systems of CNC Punching machines enable us to create parts with exacting specifications. We can precisely control the size, shape, and location of holes, slots, and other features, which are essential for the proper assembly and operation of appliances. For instance, in the production of refrigerator shelves, CNC Punching ensures that the holes for attaching brackets are drilled with pinpoint accuracy, guaranteeing a secure fit. This precision eliminates the risk of misalignment and ensures consistent quality across all our products. By delivering components with precise dimensions and flawless finishes, we enhance the reliability and performance of our household appliances, earning the trust of our customers.

3. Unleashing Design Creativity with CNC Punching

In an industry where product design can set brands apart, CNC Punching offers us the freedom to unleash our creativity and develop innovative household appliances. Using computer-aided design (CAD) software, we can create intricate and aesthetically pleasing designs that were previously difficult to achieve with traditional punching methods. CNC Punching machines can then bring these designs to life with remarkable accuracy on various materials, such as stainless steel, aluminum, and galvanized sheet metal. For example, we can incorporate unique patterns and cutouts on the exteriors of microwave ovens or air conditioners, adding a touch of style and sophistication. The ability to quickly prototype and modify designs using CNC Punching also allows us to respond rapidly to changing consumer preferences and market trends, giving us a competitive edge in the marketplace.

4. Cost – Effective Manufacturing Solutions with CNC Punching

CNC Punching has proven to be a cost-effective solution for our household appliance manufacturing operations. Although the initial investment in CNC Punching machines may be significant, the long-term benefits far outweigh the costs. By automating the punching process, we reduce labor costs associated with manual punching and minimize the need for rework due to errors. The efficient use of materials through optimized nesting and layout planning in CNC Punching also helps us reduce material waste, saving on raw material expenses. Additionally, the increased production speed and productivity allow us to spread our fixed costs over a larger volume of products, further reducing the cost per unit. These cost savings enable us to offer high-quality household appliances at competitive prices, making our products more accessible to consumers.

5. Pioneering Sustainable Manufacturing with CNC Punching

As the demand for sustainable products grows in the household appliance industry, CNC Punching is playing a vital role in our efforts to reduce our environmental impact. The precision of CNC Punching minimizes material waste, as we can optimize the use of raw materials through efficient punching patterns. This not only reduces the consumption of resources but also decreases the amount of waste sent to landfills. Moreover, the long lifespan and reliability of components produced by CNC Punching contribute to the durability of our household appliances, reducing the need for frequent replacements. By embracing CNC Punching in our manufacturing processes, we are taking a step towards a more sustainable future, meeting the expectations of environmentally conscious consumers and contributing to the global effort to protect the planet.