In the dynamic and competitive packaging industry, China stamping parts have emerged as a crucial driving force, significantly contributing to the creation of innovative, reliable, and cost – effective packaging solutions. Leveraging advanced manufacturing technologies, rich production experience, and a commitment to quality, Chinese manufacturers produce a diverse range of stamping parts that meet the multifaceted needs of the packaging sector. From enhancing the structural integrity of packaging containers to improving the efficiency of assembly processes, China stamping parts play an indispensable role in our efforts to deliver high – quality packaging products that safeguard goods and captivate consumers.

1. China Stamping Parts: Fabricating Robust Metal Packaging Containers

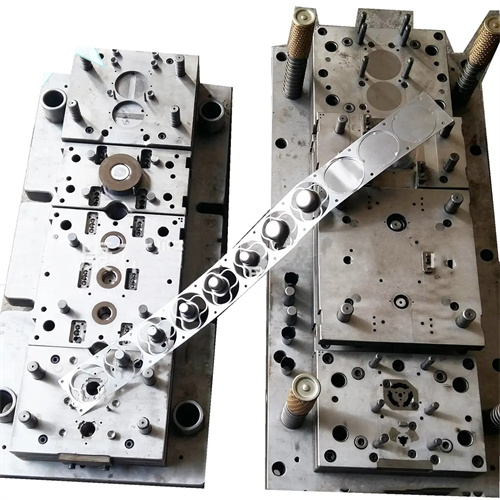

For industries that demand secure and durable packaging, such as the food, beverage, and chemical sectors, China stamping parts are instrumental in manufacturing high – quality metal packaging containers. We utilize these parts to produce cans, tins, and other metal vessels with precision and consistency. By stamping metal sheets with advanced dies, we can create containers with accurate dimensions, seamless joints, and smooth surfaces. For example, in the production of food cans, China – made stamping parts ensure that each can has a uniform wall thickness, providing excellent protection for the contents. The high – precision stamping process also allows for the incorporation of features like easy – open tabs and embossed designs, enhancing both the functionality and aesthetic appeal of the packaging. These robust metal containers, made possible by China stamping parts, not only keep products fresh and safe but also withstand the rigors of transportation and handling.

2. China Stamping Parts: Creating Structural Supports for Large – Scale Packaging

In large – scale packaging applications, such as wooden crates for heavy machinery or industrial equipment, reliable structural supports are essential. China stamping parts enable us to produce metal brackets, angles, and fasteners that reinforce these packaging structures. These stamping parts are manufactured with precise hole patterns and shapes, ensuring easy installation and a secure fit. For instance, when assembling a large wooden crate for shipping heavy industrial machinery, China – made stamping parts, like metal corner brackets, provide additional strength and stability. The high – quality metals used in these stamping parts, combined with the accuracy of the manufacturing process, ensure that the structural supports can withstand the stresses of handling, stacking, and transportation, safeguarding the packaged goods throughout the supply chain.

3. China Stamping Parts: Designing Decorative Metal Elements for Aesthetic Packaging

In the consumer goods market, the visual appeal of packaging often plays a decisive role in attracting customers. China stamping parts allow us to create intricate and eye – catching decorative metal elements for packaging. We can stamp metal sheets into various shapes, patterns, and textures, such as embossed logos, foil – stamped designs, and metallic accents. For example, in luxury product packaging, China – made stamping parts are used to produce metal plates with engraved brand names or ornate patterns, adding a touch of elegance and exclusivity. The precision of the stamping process ensures that these decorative elements are of the highest quality, with sharp details and consistent finishes, making the packaging stand out on the shelves and enhancing the overall brand image.

4. China Stamping Parts: Manufacturing Functional Closures for Packaging

Secure closures are vital for maintaining the integrity of packaged products. China stamping parts enable us to design and manufacture a wide variety of functional closures, such as snap – on lids, twist – off caps, and toggle latches. These closures are stamped with precise geometries and tolerances to ensure a tight and reliable seal. For example, in the packaging of cosmetics and personal care products, China – made stamping parts are used to produce metal caps that provide a secure closure, preventing leakage and contamination. The spring – loaded mechanisms and interlocking features of these closures, made possible by stamping technology, are designed for easy use by consumers while maintaining a high level of security. Additionally, the durability of these stamping – made closures ensures that they can withstand repeated opening and closing without losing their functionality.

5. China Stamping Parts: Facilitating Cost – Effective and Sustainable Packaging Production

China stamping parts offer significant advantages in terms of cost – effectiveness and sustainability in packaging production. With advanced automated stamping equipment and efficient production processes, we can produce large quantities of stamping parts in a short time while maintaining strict quality control. This high – volume production reduces the cost per unit, making our packaging solutions more affordable. Moreover, China stamping parts contribute to sustainable packaging practices. By optimizing material usage and minimizing waste during the stamping process, we can reduce our environmental footprint. Additionally, metals used in stamping parts are highly recyclable, promoting the circular economy. The combination of cost – effectiveness and sustainability provided by China stamping parts allows us to offer packaging solutions that meet the demands of both the market and the environment.