In the dynamic landscape of the packaging industry, we’ve harnessed the power of CNC Punching to revolutionize our production processes, ensuring efficiency, precision, and versatility in crafting diverse packaging solutions. This technology has not only optimized our manufacturing workflows but also empowered us to meet the ever-evolving demands of consumers and businesses alike. By integrating CNC Punching into our operations, we’ve been able to produce high-quality packaging products that protect goods, enhance brand appeal, and contribute to sustainable practices.

1. Elevating Production Efficiency with CNC Punching

CNC Punching has been a game-changer in boosting our production efficiency within the packaging industry. Traditional manual punching methods were labor-intensive and time-consuming, often resulting in inconsistent output. However, with CNC Punching machines, we can automate the punching process, enabling us to rapidly produce large quantities of packaging components. These machines are programmed to execute complex punching patterns with remarkable speed and accuracy, significantly reducing production lead times. Whether we’re manufacturing cardboard boxes, plastic containers, or metal packaging trays, CNC Punching allows us to meet tight deadlines and handle high-volume orders with ease, giving us a competitive edge in the market.

2. Achieving Precision and Consistency through CNC Punching

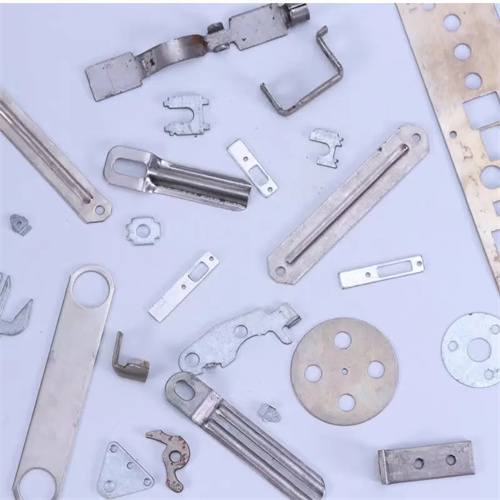

Precision is paramount in the packaging industry, and CNC Punching has enabled us to achieve unparalleled accuracy in our products. The advanced control systems of CNC Punching machines ensure that each punch is executed with pinpoint precision, creating uniform holes, slots, and shapes in packaging materials. This level of precision is crucial for ensuring proper assembly of packaging components, as well as for accommodating features like closures, handles, and inserts. By eliminating human error and maintaining consistent quality, we can enhance the functionality and aesthetics of our packaging, providing our customers with reliable and visually appealing solutions.

3. Unlocking Design Versatility with CNC Punching

In an industry where packaging design plays a vital role in brand differentiation, CNC Punching has given us the freedom to create innovative and eye-catching packaging solutions. The flexibility of CNC Punching allows us to translate intricate design concepts into reality, whether it’s adding unique patterns, cutouts, or embossed details to packaging materials. With the help of computer-aided design (CAD) software, we can easily modify and customize designs, quickly prototyping new packaging ideas and bringing them to market faster. This design versatility not only helps our customers stand out on the shelves but also allows us to cater to diverse product requirements and market trends.

4. Cost-Effectiveness Gained from CNC Punching in Packaging

CNC Punching has also proven to be a cost-effective solution for our packaging production. While the initial investment in CNC Punching machines may seem significant, the long-term benefits far outweigh the costs. By automating the punching process, we’ve reduced labor costs associated with manual punching and minimized the need for rework due to errors. Additionally, the efficient use of materials through optimized nesting and layout planning in CNC Punching helps us reduce material waste, saving on raw material expenses. These cost savings, combined with increased productivity and improved product quality, contribute to a more profitable and sustainable packaging business.

5. Future Horizons of CNC Punching in the Packaging Industry

As the packaging industry continues to embrace technological advancements and sustainability initiatives, the role of CNC Punching is set to become even more significant. We anticipate further integration of CNC Punching with other digital manufacturing technologies, such as 3D printing and laser cutting, to create more complex and multifunctional packaging solutions. Moreover, with the growing focus on eco-friendly packaging, CNC Punching will enable us to develop innovative designs that use less material, are easier to recycle, and have a lower environmental impact. We’re excited about the future possibilities that CNC Punching holds for the packaging industry and are committed to leveraging this technology to drive continuous improvement and innovation in our products and processes.