In the competitive and innovation – driven world of sports goods manufacturing, sheet metal stamping has become an invaluable technique for us. As we strive to produce sports equipment that enhances performance, durability, and comfort while meeting the diverse needs of athletes at all levels, sheet metal stamping offers a wide array of benefits. It enables us to create precision – engineered components, streamline production, and explore new design possibilities. From the frames of bicycles to the components of fitness equipment, sheet metal stamping plays a pivotal role in shaping high – quality sports goods that empower athletes to excel in their respective fields.

1. High – performance Component Production with Sheet Metal Stamping in Sports Goods

Sheet metal stamping allows us to manufacture high – performance components that are essential for the functionality of sports equipment. When crafting the frames of high – end bicycles, for instance, sheet metal stamping is employed to shape lightweight yet robust metal tubes. The advanced die – making technology combined with precise stamping processes ensures that the tubes have consistent wall thicknesses and accurate geometries, providing optimal strength – to – weight ratios. This results in bicycles that are not only easy to maneuver but also capable of withstanding the rigors of intense cycling. Similarly, in the production of golf club heads, sheet metal stamping helps us create complex internal structures that enhance the club’s aerodynamics and improve the golfer’s swing, ultimately leading to better ball control and distance. These precisely stamped components significantly elevate the performance of sports goods, giving athletes a competitive edge.

2. Accelerating Sports Goods Manufacturing with Sheet Metal Stamping

Efficiency is crucial in the sports goods industry, where market demands can fluctuate rapidly. Sheet metal stamping offers us a significant boost in production speed, enabling us to meet tight deadlines and satisfy high – volume orders. High – speed sheet metal stamping machines can operate at rapid cycles, producing numerous components in a short period. When manufacturing large batches of sports equipment, such as tennis rackets or hockey sticks, we can use sheet metal stamping to quickly produce metal parts like brackets, shafts, and connectors. This high – volume production capability ensures that we can keep up with the demands of sports enthusiasts, whether it’s preparing for the peak shopping seasons or fulfilling orders from sports teams and clubs. Moreover, the automated nature of sheet metal stamping reduces human error and increases overall productivity, allowing us to deliver products to the market more quickly.

3. Cost – effective Solutions through Sheet Metal Stamping in Sports Goods Production

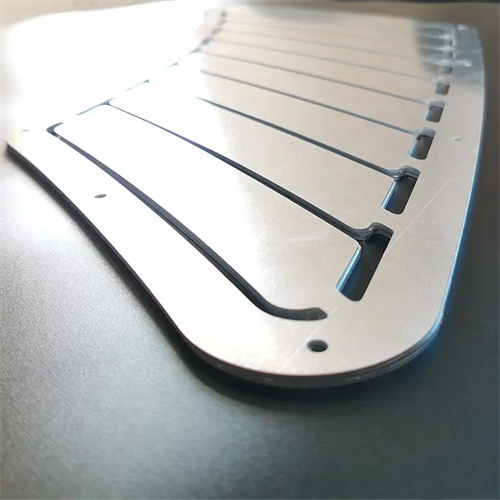

Cost control is a key consideration in sports goods manufacturing, and sheet metal stamping provides us with practical cost – saving solutions. While the initial investment in sheet metal stamping equipment and dies may seem substantial, the long – term benefits make it a worthwhile investment. The high production efficiency of sheet metal stamping reduces the cost per unit of components. By producing components in large quantities, we can take advantage of economies of scale, spreading fixed costs over a greater number of units. For example, when manufacturing metal components for running shoes, such as eyelets and support plates, sheet metal stamping can produce them at a lower cost compared to other manufacturing methods. Additionally, the optimized use of materials in sheet metal stamping minimizes waste, as metal sheets can be nested and cut precisely to maximize material utilization. This efficient resource use, combined with reduced labor costs due to automation, makes sheet metal stamping an economically viable option for our sports goods production.

4. Material Adaptability in Sheet Metal Stamping for Sports Equipment Components

The sports goods industry requires the use of diverse materials to meet different performance requirements, and sheet metal stamping offers us the flexibility to work with a wide range of materials. We can utilize materials such as aluminum, stainless steel, and titanium, each with its own unique properties. Aluminum is often favored for its lightweight nature and good corrosion resistance, making it suitable for components like bicycle frames and golf club heads where weight reduction is crucial. Stainless steel provides excellent durability and strength, making it ideal for parts that need to withstand heavy use, such as the frames of fitness equipment. Titanium, known for its high strength – to – weight ratio and biocompatibility, is used in specialized sports equipment like orthopedic braces. Sheet metal stamping can handle these materials effectively. By adjusting the stamping parameters and die designs according to the material’s characteristics, we can ensure that the components are formed accurately and retain their desired mechanical properties, enhancing the performance and longevity of the sports equipment.

5. Customization and Innovation in Sports Goods via Sheet Metal Stamping

In today’s sports market, consumers increasingly seek customized and innovative sports equipment that suits their individual preferences and playing styles. Sheet metal stamping allows us to offer a high level of customization in sports goods design. We can create unique patterns, logos, and shapes on metal components through the stamping process, enabling athletes to personalize their equipment. For example, we can stamp a professional athlete’s signature or team logo on the metal parts of their sports gear, adding a touch of exclusivity. Moreover, sheet metal stamping encourages innovation in sports goods design. We can experiment with new geometries and structures, such as creating aerodynamic shapes for cycling helmets or ergonomic designs for weightlifting bars. This ability to customize and innovate through sheet metal stamping helps us meet the evolving needs of sports enthusiasts and stay competitive in the dynamic sports goods industry.