In the vibrant and imaginative world of the toy industry, sheet metal stamping has emerged as an essential and versatile manufacturing technique for us. As we strive to create toys that are not only engaging, fun, and safe but also cost – effective and durable, sheet metal stamping offers a multitude of benefits. It enables us to produce high – quality components with precision, accelerate production processes, and bring innovative designs to life. From intricate metal parts in model toys to robust structural elements in outdoor play equipment, sheet metal stamping plays a crucial role in shaping the toys that capture the hearts and imaginations of children around the world.

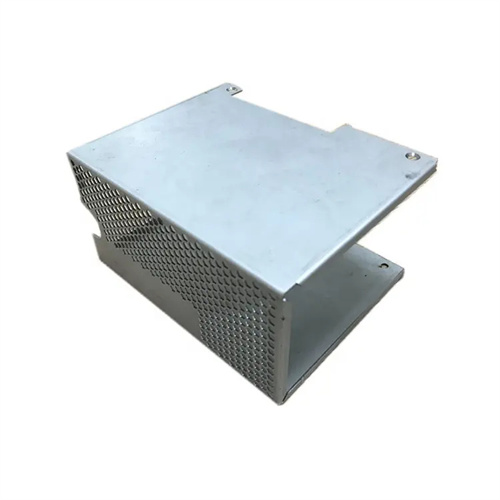

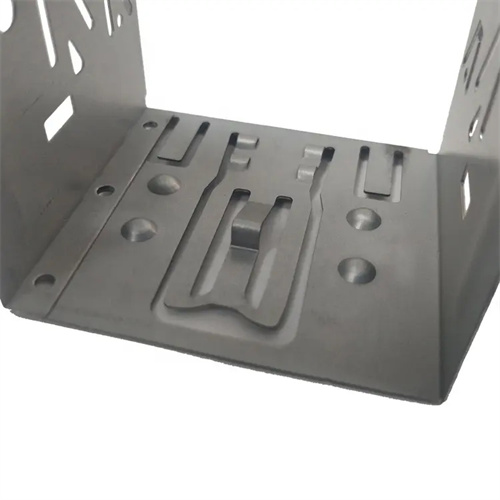

1. Precision – crafted Toy Components by Sheet Metal Stamping

Sheet metal stamping empowers us to fabricate precision – crafted components that are the building blocks of high – quality toys. When manufacturing die – cast model cars, for example, sheet metal stamping is used to create tiny yet detailed parts such as grilles, wheels, and door handles. The advanced die – making technology combined with high – speed stamping presses allows us to form these components with remarkable accuracy, ensuring that every curve and contour is faithfully reproduced. This level of precision not only enhances the visual appeal of the toys but also contributes to their functionality. For instance, precisely stamped gears in mechanical toys ensure smooth and reliable movement, providing children with an engaging and realistic play experience.

2. Boosting Toy Production Efficiency with Sheet Metal Stamping

Efficiency is key in the toy industry, where seasonal demands and market trends can change rapidly. Sheet metal stamping offers us a significant advantage by enabling high – speed and high – volume production. High – speed sheet metal stamping machines can operate at extremely fast cycles, producing hundreds of components per minute. When manufacturing popular action figures in large quantities, we can use sheet metal stamping to quickly produce metal accessories like swords, shields, and armor pieces. This high – volume production capability allows us to meet tight deadlines and satisfy the sudden surges in consumer demand, especially during peak shopping seasons such as the holidays. Additionally, the automated nature of sheet metal stamping reduces the need for extensive manual labor, minimizing errors and further enhancing the overall production efficiency of our toy manufacturing operations.

3. Cost – effective Toy Manufacturing via Sheet Metal Stamping

Cost control is a crucial aspect of toy production, and sheet metal stamping provides us with effective cost – saving solutions. Although the initial investment in sheet metal stamping equipment and dies can be substantial, the long – term benefits far outweigh the costs. The high production speed and efficiency of sheet metal stamping reduce the cost per unit of components. By producing components in large batches, we can take advantage of economies of scale, spreading the fixed costs over a greater number of units. For example, when manufacturing metal parts for building block toys, sheet metal stamping can produce them at a lower cost compared to traditional manufacturing methods. Moreover, the optimized use of materials in sheet metal stamping minimizes waste, as the metal sheets can be nested and cut with precision to maximize material utilization. This efficient use of resources, combined with reduced labor costs due to automation, makes sheet metal stamping an economically viable option for our toy production, allowing us to offer high – quality toys at competitive prices.

4. Ensuring Toy Safety with Sheet Metal Stamping

Safety is our top priority in the toy industry, and sheet metal stamping plays an important role in ensuring the safety of our products. Sheet metal stamping produces components with consistent quality and smooth surfaces, reducing the risk of sharp edges or rough spots that could potentially harm children. When manufacturing metal parts for toys, such as the frames of ride – on toys or the structural components of outdoor play sets, sheet metal stamping ensures that the parts are formed accurately and without defects. Advanced monitoring systems integrated into sheet metal stamping equipment also help us detect any irregularities in the production process, such as variations in material thickness or stamping force, in real – time. This strict quality control throughout the sheet metal stamping process guarantees that the toys we produce meet or exceed safety standards, providing parents with peace of mind.

5. Enabling Innovation and Customization in Toy Design through Sheet Metal Stamping

In today’s competitive toy market, innovation and customization are essential for standing out. Sheet metal stamping allows us to explore new and exciting toy designs, as well as offer customized options to our customers. We can experiment with different materials, shapes, and textures to create unique and engaging toys. For example, by using sheet metal stamping to shape thin sheets of colorful metals, we can create decorative elements for toys that add a touch of novelty. Additionally, we can customize toys by stamping logos, names, or personalized messages onto metal components. This level of customization not only enhances the appeal of the toys but also allows us to meet the specific preferences of children and collectors, giving our products a competitive edge in the market.