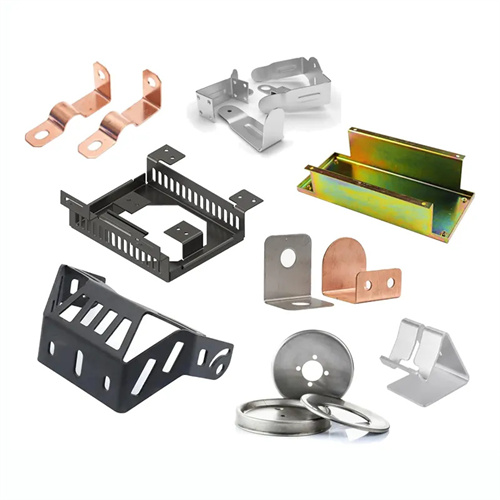

Customized China Stamping Parts Precision Bracket Metal Bracket

China stamping parts have significant advantages in the production of stamping parts, which are mainly reflected in the following aspects:

1. Strong technical strength: Chinese stamping plants have advanced stamping technology and rich production experience, and are able to manufacture high-precision, high-quality stamping parts. At the same time, these manufacturers also have strong R&D capabilities, and can continuously develop new stamping processes and products according to market demand and customer requirements.

2. Advanced equipment: Chinese stamping plants are equipped with advanced stamping equipment and molds, which can achieve efficient and accurate stamping processing. These equipment not only improve production efficiency, but also ensure the quality and stability of products.

3. Cost control advantage: Chinese stamping plants perform well in production cost control. By optimizing the production process, improving equipment utilization, and reducing labor costs, these manufacturers are able to provide customers with competitive prices while ensuring product quality.

4. Short delivery time: Due to the efficient production capacity and strict production management of China stamping parts, it can complete the production and delivery of customer orders in a short time. This fast delivery capability helps customers meet market demand in a timely manner and improve competitiveness.

5. Customized service: Chinese stamping factory pays great attention to customer needs and can provide personalized customized services. No matter what shape, size or material the customer needs, these manufacturers can design and produce according to the requirements to meet the customer’s special requirements.

Precision metal bracket is a metal structural component with high precision, quality, and performance characteristics.

In the industrial field, they are commonly used to support and fix critical equipment and components. For example, in CNC machine tools, precision metal brackets can provide stable support for the tool system, ensuring machining accuracy.

In the electronics industry, they are important components for circuit board installation and fixation. Like the interior of high-end servers, precision metal brackets can ensure the accurate installation and reliable connection of multiple circuit boards, which helps improve the operational stability of the equipment.

In medical equipment, precision metal brackets also play a crucial role. For example, in some precision testing instruments, precise positioning and support are provided for key components.

The advantages of precision metal brackets include:

High precision: able to meet extremely strict dimensional and positional tolerance requirements.

High strength and rigidity: able to withstand large loads and external forces.

Good corrosion resistance: Suitable for various harsh working environments.

In the ever-evolving landscape of manufacturing, we take immense pride in our role as providers of customized China stamping parts, particularly our precision metal brackets. These brackets may seem like small components, but they play a crucial and often overlooked role in countless applications across diverse industries, and we are dedicated to delivering products that combine unrivaled precision, exceptional durability, and tailored solutions.

Precision is the hallmark of our customized metal brackets. In today’s high-tech and highly competitive market, even the slightest deviation in a bracket’s dimensions can lead to significant issues in the overall assembly or system it supports. That’s why we leverage the latest in stamping technology, including advanced CNC – controlled stamping presses and high-precision dies. Our state-of-the-art equipment, paired with meticulous programming and skilled operators, allows us to create metal brackets with tolerances that meet the most exacting standards. Whether it’s a bracket for a delicate electronic device that requires micron-level precision or a structural bracket for heavy machinery, we ensure that every hole, bend, and edge is crafted with pinpoint accuracy. This precision not only guarantees a perfect fit within the final product but also enhances the overall performance and reliability of the system.

Durability is another key aspect we prioritize in our customized stamping parts. We understand that metal brackets are often subjected to various forces, vibrations, and environmental conditions throughout their lifespan. To address this, we carefully select high-quality materials, such as stainless steel, aluminum alloys, and high-strength carbon steel, based on the specific requirements of each project. Our stamping process further enhances the material’s structural integrity, as the controlled deformation during stamping aligns the metal’s internal grain structure, making the brackets more resistant to fatigue, wear, and corrosion. Whether it’s a bracket that will operate in a harsh industrial environment or one that needs to withstand the rigors of constant movement in a vehicle, our products are built to last, reducing the need for frequent replacements and minimizing downtime for our clients.

What truly sets us apart is our commitment to customization. We recognize that no two projects are identical, and one-size-fits-all solutions simply won’t suffice. Our team of experienced engineers and designers works closely with clients from the very beginning, actively listening to their needs, understanding their application requirements, and providing expert advice. We use advanced 3D modeling and simulation software to develop customized designs that optimize the bracket’s functionality, strength, and cost-effectiveness. From unique shapes and sizes to specialized features like integrated mounting points, reinforcing ribs, or customized surface finishes, we have the capabilities to bring our clients’ visions to life. This collaborative approach ensures that the final product not only meets but exceeds their expectations, providing them with a competitive edge in the market.

As China-based manufacturers, we also benefit from a robust and efficient manufacturing ecosystem. Our strategic location allows us to access a vast network of reliable suppliers for raw materials, components, and services, ensuring a steady supply chain and cost-effective sourcing. Additionally, our large-scale production facilities, combined with streamlined production processes and strict quality control measures, enable us to offer competitive pricing without compromising on quality. We can handle projects of all sizes, from small-batch custom orders for niche applications to large-volume production runs for mass-market products, all while maintaining the same high level of precision and quality.

In conclusion, our customized China stamping parts, especially precision metal brackets, represent the perfect blend of precision, durability, customization, and cost-effectiveness. We are dedicated to providing our clients with top-notch products that meet the highest standards of quality and performance. Whether it’s for the automotive, aerospace, electronics, or any other industry, we are confident that our metal brackets will contribute to the success of our clients’ projects and help them achieve their business goals.