China stamping parts have significant advantages in the manufacturing industry, and these advantages are reflected in many aspects, making stamping parts in China and even the global marketStrong competitiveness. Here are the main advantages of stamping parts in China:

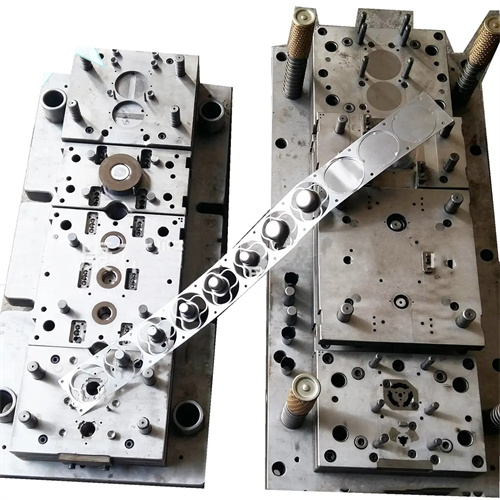

1. High-precision processing ability: China stamping parts are manufactured by molds and presses, which can realize high-precision processing of metal materials. This high-precision plus It not only meets the strict requirements for the accuracy of parts in the fields of precision instruments and auto parts, but also improves the overall quality and performance of the product.

2. Efficient production speed: The stamping process of China stamping parts can achieve high-speed continuous stamping, which greatly improves the production efficiency. Through the cooperation of molds and automation equipment It can achieve large-scale mass production, effectively shorten the production cycle and reduce production costs.

3. Complex shape processing ability: China stamping parts can realize a variety of shape processing of metal materials, including plane, bending, stretching, convex and concave, etc. this Stamping parts can meet the needs of different industries and fields for the diversification of parts shapes, and have a wide range of applications.

4. Excellent material utilization: During the stamping process, the raw materials are cut, flanged, formed and other operations, which can minimize material waste. This efficient material utilization not only reduces production costs, but also meets the requirements of environmentally sustainable development.

5. Good product performance: China stamping parts have been processed by many times, and the surface is free of defects and gas defects, and has excellent strength and rigidity. This is excellent. The performance of the product makes the stamped parts perform well when subjected to external forces or loads, and can meet various use requirements.

6. Wide range of market applications: stamping parts have a wide range of applications in automobile manufacturing, home appliance production, electronic equipment manufacturing, construction and other fields. follow with the continuous expansion of market demand and the continuous progress of technology, the application field of stamping parts will be further expanded.

In the global manufacturing landscape, we, as Chinese stamping parts manufacturers, take pride in the distinct advantages we bring to the table. Our contributions to the industry are shaped by a combination of factors that enable us to deliver high-quality products efficiently and competitively.

One of the most significant advantages of China stamping parts lies in our ability to achieve economies of scale. With a vast manufacturing infrastructure and a large pool of skilled labor, we can produce stamping parts in large volumes. This scale of production allows us to spread the fixed costs of tooling, equipment, and overhead across a greater number of units, resulting in lower per-unit costs. Whether it’s for automotive components, electronic parts, or industrial machinery, our high-volume production capabilities enable us to offer competitive pricing without compromising on quality. This makes Chinese stamping parts an attractive choice for businesses worldwide, from small startups to large multinational corporations.

Our advanced manufacturing technology is another key advantage. Over the years, we have made substantial investments in state-of-the-art stamping equipment, including high-speed presses, precision dies, and automated production lines. These technologies allow us to produce stamping parts with exceptional accuracy and consistency. For example, our high-speed presses can operate at speeds of hundreds of strokes per minute, ensuring rapid production while maintaining tight tolerances. Additionally, we utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to optimize the design and production of stamping dies, reducing lead times and improving the quality of the final parts.

Flexibility is deeply ingrained in our manufacturing approach. We understand that different customers have unique requirements, and we are well-equipped to handle a wide range of customization requests. Whether it’s producing stamping parts in small batches for prototyping or large quantities for mass production, we can adapt our processes accordingly. Our experienced engineers and technicians work closely with customers to understand their specific needs and develop tailored solutions. We can modify existing designs, create new tooling, and adjust production parameters to meet the most demanding specifications. This flexibility allows us to serve diverse industries, from automotive and aerospace to electronics and consumer goods.

Quality control is a top priority for us. We have established comprehensive quality management systems that adhere to international standards such as ISO 9001. From the selection of raw materials to the final inspection of finished products, we implement strict quality control measures at every stage of production. Our quality control teams use advanced testing equipment and techniques to ensure that each stamping part meets or exceeds the required specifications. For example, we conduct dimensional inspections, material analysis, and functional testing to identify and address any potential issues before the parts are shipped to customers. This commitment to quality has earned us a reputation for reliability and has made Chinese stamping parts a trusted choice in the global market.

In addition to our manufacturing capabilities, we also benefit from a well-developed supply chain ecosystem. China has a vast network of suppliers that can provide raw materials, components, and services at competitive prices and with short lead times. This allows us to source the necessary inputs efficiently, reducing costs and improving our overall responsiveness to customer demands. Furthermore, our proximity to major shipping ports and transportation hubs enables us to deliver products quickly and cost-effectively to customers around the world.

Another advantage of China stamping parts is our focus on innovation and continuous improvement. We invest heavily in research and development to explore new materials, processes, and technologies that can enhance the performance and efficiency of our stamping parts. For example, we are constantly working on developing lighter and stronger materials to meet the growing demand for fuel-efficient vehicles and sustainable products. We also collaborate with universities and research institutions to stay at the forefront of technological advancements and to apply the latest innovations in our manufacturing processes.

In conclusion, the advantages of China stamping parts in the manufacturing industry are multifaceted. Our ability to achieve economies of scale, combined with advanced technology, flexibility, strict quality control, a well-developed supply chain, and a focus on innovation, makes us a preferred partner for businesses worldwide. We are committed to continuously improving our capabilities and services to meet the evolving needs of the global market and to contribute to the success of our customers.