CNC stamping technology plays a crucial role in the manufacturing process of computer cases. CNC stamping has brought many advantages to the production of chassis.

Firstly, it can accurately create various specifications of ventilation holes, installation holes, and interface slots on the chassis. For example, to ensure good heat dissipation, even and appropriately sized ventilation holes need to be punched on the side panel of the chassis; In order to install hardware such as the motherboard and graphics card, it is necessary to precisely punch the corresponding installation holes on the chassis frame.

Secondly, CNC stamping can achieve efficient mass production. For chassis products with high demand, this technology can produce a large number of components of the same specifications in a short period of time, greatly improving production efficiency and reducing production costs.

Furthermore, it has excellent material adaptability and can handle various metal materials commonly used in chassis manufacturing, such as steel plates, aluminum alloys, etc., while ensuring that the performance of the materials is not greatly affected during the stamping process.

CNC punching is the abbreviation of digital controlled punching machine, which is an automated machine tool equipped with a program control system. The working principle is roughly as follows:

Firstly, the operator uses computer software to write the machining program for the workpiece and uploads the program to the computer control system of the CNC punching machine. Next, set machining parameters in the control system, such as tool type, cutting speed, feed rate, etc. Then, fix the workpiece to be processed on the worktable of the punching machine and position it through the fixture. Finally, the computer control system of the CNC punching machine controls the tool movement trajectory and processing parameters according to the pre written processing program, and performs punching and punching operations.

During the operation process, the operation and monitoring of the CNC punching machine are all completed in the CNC unit, which is the brain of the CNC punching machine. At the same time, operators need to constantly monitor the impact between the punch and the workpiece, and verify the cutting results after the punching is completed.

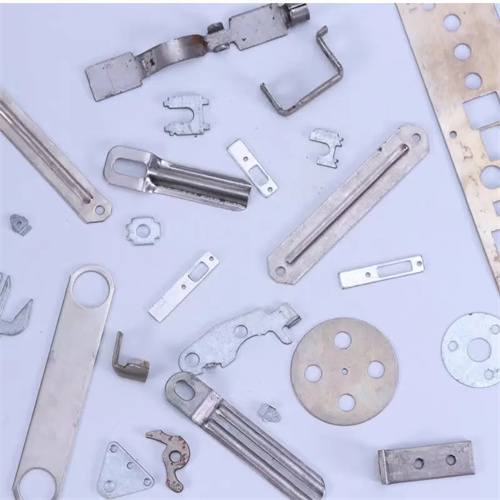

CNC punching are widely used in cold stamping processing industries such as power equipment sets, chassis and cabinets, household appliances, elevators, air conditioning, kitchen equipment, office equipment, building decoration, hardware and furniture, medical equipment, lighting fixtures, etc. When using CNC punching, it is necessary to set appropriate process parameters according to actual processing needs, such as the shape of the punch, punching hole size, punching machine stroke, number of strokes, etc., to ensure punching quality and efficiency.

In the fast-paced realm of computer hardware manufacturing, we take immense pride in our expertise in CNC punching sheet metal processing for computer cases. Our services are a harmonious blend of precision, innovation, and efficiency, designed to meet the ever-evolving demands of the tech industry.

CNC punching offers unparalleled precision when it comes to crafting computer cases. Computer components are becoming increasingly compact and powerful, and the cases that house them need to accommodate these intricate parts with utmost accuracy. Our advanced CNC punching machines are programmed using cutting-edge CAD/CAM software, ensuring that every hole, slot, and cutout is executed with pinpoint precision. Whether it’s creating precise mounting holes for motherboards, CPU coolers, and hard drives, or crafting ventilation slots to optimize airflow and prevent overheating, we can achieve the tightest tolerances. This precision not only ensures a perfect fit for all internal components but also enhances the overall structural integrity of the computer case, protecting the valuable electronics inside from damage.

Flexibility is a key strength of our CNC punching sheet metal processing for computer cases. We understand that the computer market is highly competitive, with manufacturers constantly striving to differentiate their products through unique designs. Our CNC punching technology allows for a high degree of customization, enabling us to bring even the most innovative case designs to life. From creating sleek, minimalist cases with clean lines to elaborate designs featuring complex geometric patterns and illuminated accents, we can adapt our punching process to meet a wide range of aesthetic and functional requirements. Additionally, we can easily make design changes and modifications during the production process, providing our clients with the agility they need to respond quickly to market trends and customer feedback.

Efficiency is at the heart of our CNC punching operations. Unlike traditional punching methods that may require time-consuming setup and manual adjustments, our CNC punching machines can rapidly produce computer case components with minimal human intervention. Once the design is programmed into the system, the machine can execute a series of punches with remarkable speed and consistency, significantly reducing production time. This efficiency is especially crucial in the computer industry, where short product life cycles and high demand mean that manufacturers need to get their products to market as quickly as possible. By leveraging the speed of CNC punching, we can help our clients accelerate their production schedules and gain a competitive edge.

Material selection and utilization are also critical aspects of our service. We work with a variety of high-quality sheet metals, including stainless steel, aluminum, and cold-rolled steel, each chosen for its specific properties such as strength, durability, and electromagnetic shielding capabilities. Our CNC punching process is optimized to make the most efficient use of these materials, minimizing waste through advanced nesting algorithms. These algorithms calculate the best layout for punching multiple parts on a single sheet of metal, maximizing material utilization and reducing production costs. This not only benefits our clients financially but also contributes to a more sustainable manufacturing process.

Quality control is an integral part of our CNC punching sheet metal processing for computer cases. We have implemented a comprehensive quality management system that includes rigorous inspections at every stage of production. Our quality control team uses advanced measurement tools, such as coordinate measuring machines (CMMs), to verify the accuracy of each punched part. We also conduct visual inspections to check for any surface defects or imperfections. By maintaining strict quality standards, we ensure that the computer cases we produce are not only functional and durable but also meet the high aesthetic expectations of consumers.

In conclusion, our CNC punching sheet metal processing for computer cases offers a winning combination of precision, flexibility, efficiency, material optimization, and quality control. We are dedicated to providing our clients with the highest quality computer case components that meet the demanding requirements of the modern tech industry. As the industry continues to evolve, we look forward to leveraging our expertise and technology to drive innovation and help our clients succeed in the competitive world of computer hardware manufacturing.