As an advanced processing equipment, CNC punching have many significant advantages, mainly including the following aspects:

1. High precision machining: CNC punching can achieve high-precision machining through precise control systems. Each pulse signal is output by the CNC device, allowing the moving parts of the punch to move with the set pulse equivalent, ensuring the accuracy of processing. This high-precision processing capability enables CNC punching machines to meet the production needs of many precision components.

2. Efficient production: CNC punching have the characteristics of high automation and fast processing speed. Once the machining program is set up, the machine can automatically complete the punching and punching operations, greatly reducing the time and cost of manual operations. In addition, CNC punching machines can also perform multi coordinate linkage, which is suitable for processing parts with complex shapes, further improving production efficiency.

3. Strong flexibility: CNC punching have strong flexibility and can adapt to various processing needs. When different parts need to be processed, simply replace the corresponding molds and fixtures, and rewrite the processing program to achieve fast conversion. This flexibility gives CNC punching significant advantages in frequent replacement of machined parts, small-scale product production, and new product development.

4. Easy to operate: The operation of CNC punching is relatively simple, and personnel with basic computer knowledge can get started after short-term training. In addition, CNC punching machines are usually equipped with friendly user interfaces and intuitive operating interfaces, allowing operators to easily master the skills of using the machine.

5. Low labor intensity: Due to the high degree of automation of CNC punching, operators only need to monitor the operation of the machine, without the need for a lot of physical labor. This greatly reduces the labor intensity of operators, while also helping to improve the comfort and safety of the working environment.

6. Cost savings: Although the initial investment of CNC punching may be high, due to their high efficiency, high precision, and long lifespan, cost savings can be achieved during long-term operation. In addition, CNC punching machines reduce the time for mold replacement and debugging, reduce waste in the production process, and further reduce production costs.

In our industry, custom CNC punching fabrication services have emerged as a game-changer, offering unparalleled benefits that have transformed the way we approach manufacturing projects. At the heart of our success lies our ability to provide tailored solutions that meet the unique needs of our clients, and custom CNC punching is a crucial part of that offering.

One of the most significant advantages of our custom CNC punching fabrication service is the precision it allows. Our state-of-the-art CNC punching machines are programmed with highly accurate designs, ensuring that every hole, cut, and bend is executed with pinpoint accuracy. This level of precision is essential in industries where even the slightest deviation can lead to significant issues, such as aerospace, automotive, and electronics. By eliminating human error and relying on computer-controlled systems, we can guarantee that each component we produce meets the strictest quality standards.

Another key benefit is the speed and efficiency of our custom CNC punching process. Traditional punching methods often involve time-consuming setup procedures and manual adjustments, which can slow down production and increase costs. In contrast, our CNC punching machines can be quickly programmed and reconfigured to handle different designs and materials. This flexibility allows us to adapt to changing project requirements in a timely manner, reducing lead times and getting products to market faster. Whether we’re working on a small prototype or a large-scale production run, our CNC punching technology enables us to maintain a high level of productivity without sacrificing quality.

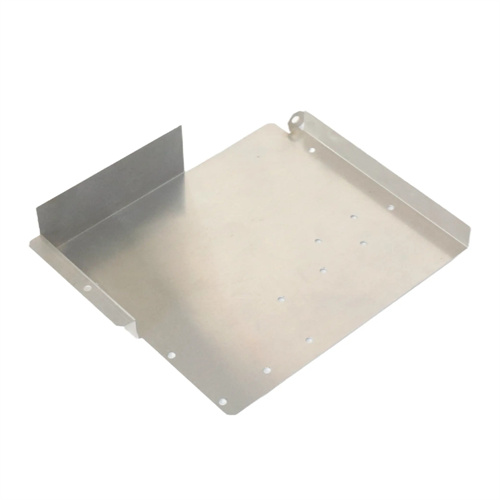

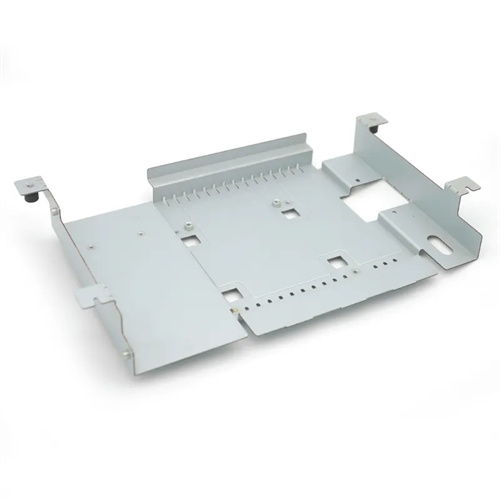

Customization is at the core of what we do, and our CNC punching fabrication service excels in this area. We understand that every client has unique specifications and design requirements, and our team of experts works closely with them to bring their visions to life. From intricate patterns and complex shapes to specific hole sizes and spacing, we have the capabilities to create customized components that are tailored to exact specifications. This level of customization not only enhances the functionality of the final product but also gives our clients a competitive edge in the market by allowing them to offer unique, one-of-a-kind solutions to their customers.

In addition to precision, speed, and customization, our custom CNC punching fabrication service also offers cost savings. While the initial investment in CNC punching equipment may be higher than traditional methods, the long-term benefits far outweigh the costs. By streamlining the production process, reducing material waste, and minimizing the need for rework, we can significantly lower overall production costs. Our ability to optimize material usage through efficient nesting techniques means that we can make the most of every sheet of metal, reducing scrap and saving our clients money. Moreover, the consistent quality and reliability of our CNC-punched components reduce the risk of product failures and costly recalls, further enhancing the value of our service.

Furthermore, our custom CNC punching fabrication service is highly versatile, capable of working with a wide range of materials. Whether it’s stainless steel, aluminum, copper, or other metals, our CNC punching machines can handle various thicknesses and hardness levels with ease. This versatility allows us to serve diverse industries, from construction and machinery manufacturing to signage and architectural design. No matter the material or application, we have the expertise and equipment to deliver high-quality, custom-fabricated components that meet or exceed our clients’ expectations.

At our company, we pride ourselves on our commitment to innovation and continuous improvement. We are constantly investing in the latest CNC punching technology and training our staff to stay at the forefront of the industry. This dedication to excellence ensures that we can provide our clients with the best possible custom CNC punching fabrication service, delivering superior products, exceptional customer service, and unbeatable value.

In conclusion, the advantages of our custom CNC punching fabrication service are numerous and far-reaching. From precision and speed to customization, cost savings, and versatility, our service offers a comprehensive solution for all your manufacturing needs. Whether you’re looking to produce a small batch of components or embark on a large-scale production project, we have the skills, experience, and technology to make it happen. Partner with us and experience the difference that custom CNC punching can make for your business.