Deep drawing technology has a wide range of applications in tableware manufacturing, bringing unique advantages and characteristics to tableware.

In the manufacturing of knives and forks, the shape of the handle and fork can be formed through deep drawing. The handle produced in this way has smooth lines, comfortable grip, and can ensure a certain level of strength and durability.

For plates and bowls, deep drawing technology can create products of various sizes and depths. The edges of the deep drawn plates and bowls are neat and smooth, and the internal surface is flat, which is not only aesthetically pleasing but also easy to clean.

Deep drawing technology is also commonly used for tableware such as spoons and spoons. Deep drawing ensures a regular shape of the spoon body and precise shaping of the spoon head, meeting different usage needs.

The deep drawing process has brought the following benefits to tableware manufacturing:

Efficient production: able to quickly mass produce tableware of the same specifications, improving production efficiency.

Cost control: In large-scale production, it helps to reduce unit costs.

Shape consistency: Ensure that the shape and size of each tableware are highly consistent.

Deep drawing technology provides an efficient and accurate production method for the tableware manufacturing industry, meeting people’s needs for beautiful, practical, and high-quality tableware.

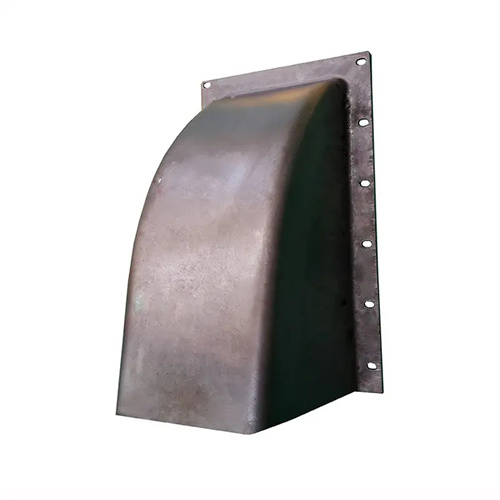

Deep drawing process is an important mechanical processing technology, which uses molds to punch a certain shaped flat blank into various open hollow parts, or to reduce the diameter and increase the height of the open hollow blank. This process can be used to manufacture thin-walled parts with cylindrical, stepped, conical, spherical, box, and other irregular shapes, and plays a significant role in the production process of industrial sectors such as automobiles, airplanes, tractors, electrical appliances, instruments, and electronics.

The basic steps of deep drawing process include fixing the material blank between the fixture and the mold, then deforming it through a punch and moving it downwards into the mold until the desired shape is obtained. This process is usually accompanied by other operations such as perforation, trimming, marking, etc. The deep drawing process can use various materials, including aluminum, non-alloy steel, stainless steel, brass, bronze, or copper, etc.

The advantages of deep drawing technology include high production efficiency, high material utilization, and high precision of parts. However, there are also some challenges, such as high mold costs, material limitations, and possible defects such as wrinkling and tearing. To overcome these challenges, precise control of process parameters, optimization of mold design, and selection of materials suitable for deep drawing processes are required.

In addition, the deep drawing process can also be combined with other stamping forming processes such as flanging, bulging, expanding, and shrinking to produce parts with more complex shapes. This makes the deep drawing process have broad application prospects in the manufacturing field.

In the world of culinary artistry and everyday dining, we, as Chinese suppliers specializing in custom deep drawing for tableware, are dedicated to crafting products that seamlessly blend functionality, aesthetics, and durability. Our deep drawing expertise has positioned us as a leading force in the tableware industry, meeting the diverse needs of clients both at home and abroad.

When it comes to custom deep drawing for tableware, our proficiency in handling various materials sets us apart. We work with premium metals such as stainless steel, copper, and aluminum, each offering unique qualities. Stainless steel, renowned for its corrosion resistance, hygienic properties, and sleek appearance, is a popular choice for everyday tableware. Our deep drawing process transforms flat sheets of stainless steel into bowls, plates, and cups with smooth, seamless surfaces that are not only easy to clean but also resistant to stains and scratches. Copper, on the other hand, adds a touch of elegance and warmth to table settings. Through deep drawing, we can create intricate designs and shapes with copper, leveraging its malleability to produce one-of-a-kind pieces that become the centerpiece of any dining experience. Aluminum, with its lightweight nature, is ideal for tableware that requires portability without sacrificing strength.

Precision is the cornerstone of our deep drawing process for tableware. Every curve, edge, and detail matters in creating tableware that is not only visually appealing but also comfortable to use. Our state-of-the-art deep drawing machinery, paired with meticulously designed dies, ensures that each piece of tableware is crafted with exacting standards. Whether it’s the precise depth of a soup bowl or the delicate curvature of a wine glass stem, we pay close attention to every dimension. This precision also extends to the uniformity of thickness across the tableware, guaranteeing consistent quality and performance.

Customization is where our services truly shine. We understand that tableware is not just a functional item but also a reflection of personal style and brand identity. Our team of skilled designers and engineers collaborates closely with clients to bring their visions to life. From customizing the shape and size of tableware to incorporating unique patterns, logos, or engravings, we have the capabilities to create truly bespoke pieces. For restaurants and hotels looking to establish a distinctive dining experience, we can design tableware that aligns with their overall theme and decor. For individuals seeking personalized gifts, we offer a wide range of customization options to make each piece special.

Efficiency is deeply ingrained in our production processes. Our large-scale manufacturing facilities are equipped with high-speed deep drawing presses and automated production lines, enabling us to handle orders of all sizes with ease. We have optimized our workflows to minimize production time without compromising on quality. From the rapid setup of dies to the seamless transfer of materials between production stages, every aspect of our operation is designed to enhance productivity. This means that we can meet tight deadlines and deliver orders promptly, ensuring that our clients can get their custom tableware to market or into use as quickly as possible.

Quality control is an integral part of our commitment to excellence. We have implemented a rigorous quality management system that monitors every stage of production, from raw material inspection to the final packaging of the finished products. Our quality control team uses advanced testing methods to check for any defects, such as cracks, dents, or uneven surfaces. We also conduct durability tests to ensure that our tableware can withstand the rigors of daily use. By maintaining such high-quality standards, we build trust with our clients and ensure that our custom deep-drawn tableware exceeds their expectations.

In conclusion, as Chinese suppliers of custom deep drawing for tableware, we offer a comprehensive solution that combines material expertise, precision, customization, efficiency, and quality. We are passionate about creating tableware that not only enhances the dining experience but also stands the test of time. Whether it’s for commercial use or personal enjoyment, we look forward to continuing to provide innovative and high-quality tableware solutions to clients around the world.