Sheet metal stamping plays an important role in the manufacturing of computer cases and industrial control cases.

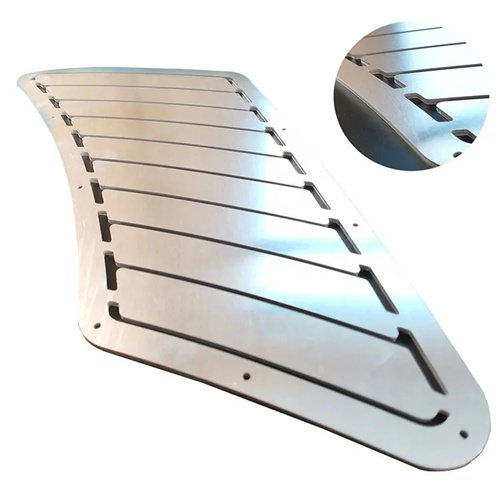

For computer cases, sheet metal stamping can create a delicate appearance. The side panels, front panels, and top panels can be stamped with beautiful heat dissipation holes, interface openings, and unique shapes, which not only meet the heat dissipation needs but also add aesthetics. At the same time, the internal brackets and partitions can also be precisely formed through stamping, providing stable support and reasonable layout space for hardware.

In the manufacturing of industrial control cases, sheet metal stamping plays a crucial role. Due to the special nature of the industrial control environment, there are extremely high requirements for the protection and stability of the chassis. By using sheet metal stamping, a sturdy and durable shell can be manufactured that can withstand harsh working conditions. Stamped reinforcement ribs and folded edges can enhance the structural strength of the chassis, ensuring that it still maintains good performance under vibration and impact.

Sheet metal stamping brings many advantages to the manufacturing of these two types of chassis:

High precision: able to achieve precise size and shape control, ensuring perfect coordination of various components in the chassis.

Efficient production: suitable for large-scale production, improving production efficiency, and reducing production costs.

Material diversity: Multiple suitable metal materials can be used to meet different performance and cost requirements.

Sheet metal stamping as an important metal processing technology, has multiple significant advantages, making it occupy an important position in the manufacturing industry. The following are the main advantages of sheet metal stamping:

Long mold life: Sheet metal stamping molds have been carefully designed and manufactured, with high durability and stability. Under normal usage conditions, the mold can withstand multiple stamping without being easily damaged, thereby reducing maintenance costs and replacement frequency.

Strong adaptability: Sheet metal stamping technology can adapt to different materials, thicknesses, and shapes of metal sheets. By changing molds and adjusting process parameters, it is easy to produce products of different specifications and shapes to meet the diverse needs of the market.

Cost effectiveness: Although the initial mold production cost may be high, the individual product cost of sheet metal stamping is relatively low in large-scale production. This is because the stamping process can achieve efficient and continuous production, reducing labor and time costs.

In the ever-evolving technological and industrial landscapes, we recognize the critical role that sheet metal stamping plays in crafting computer and industrial control cabinets. These cabinets serve as the protective and functional enclosures for sensitive electronic components and complex control systems, and our sheet metal stamping expertise is dedicated to delivering solutions that meet the highest standards of quality, durability, and precision.

When it comes to computer cabinets, precision is non-negotiable. The internal components of computers, from motherboards to hard drives, require a snug and secure fit within the cabinet. Our sheet metal stamping process enables us to create parts with exacting dimensions, ensuring that every slot, hole, and panel aligns perfectly. We use advanced CAD/CAM technology to design dies that can produce intricate shapes and cutouts for cable management, ventilation, and component mounting. Whether it’s a compact desktop computer cabinet or a large server rack, our stamping process guarantees that the final product provides optimal protection and functionality. The ability to stamp multiple parts in a single production run also allows us to maintain consistency across a range of computer cabinet models, reducing the need for time-consuming adjustments and ensuring a seamless assembly process.

Industrial control cabinets face even more demanding requirements due to the harsh environments in which they often operate. These cabinets house critical control systems that manage industrial processes, and they must withstand factors such as dust, moisture, vibrations, and extreme temperatures. Our sheet metal stamping service focuses on using high-quality materials, such as stainless steel and heavy-gauge steel, to create robust cabinets that can endure these challenging conditions. The stamping process enhances the structural integrity of the metal, making the cabinets more resistant to deformation and damage. We also pay close attention to details like precise bending angles and seamless joints, as these elements contribute to the cabinet’s overall strength and sealing capabilities. By ensuring that the industrial control cabinets are well-built, we help safeguard the reliability of the control systems inside, minimizing the risk of costly downtime and equipment failures in industrial operations.

Cost-effectiveness is a key advantage of our sheet metal stamping for computer and industrial control cabinets. For high-volume production, the economies of scale achieved through stamping significantly reduce the per-unit cost. Once the dies are developed, our automated stamping presses can produce a large number of parts efficiently, spreading the cost of tooling and labor across a substantial quantity of cabinets. Additionally, we optimize material usage by carefully nesting parts on the sheet metal, minimizing waste and further lowering production costs. This cost-efficient approach allows us to offer competitive pricing to our clients, whether they are computer manufacturers looking to produce cabinets in bulk or industrial companies in need of custom control cabinets for their facilities.

Flexibility is another strength of our sheet metal stamping service. We understand that different computer and industrial control cabinet projects have unique specifications. Our team of experienced engineers and designers works closely with clients to translate their requirements into customized solutions. From customizing the size and shape of the cabinets to incorporating specialized features like lockable doors, removable panels, or built-in cooling systems, we can adapt our stamping process and die designs accordingly. This flexibility ensures that the cabinets we produce not only meet the functional needs of our clients but also fit seamlessly into their existing infrastructure and workflows.

Quality control is ingrained in every step of our sheet metal stamping process for computer and industrial control cabinets. We conduct rigorous inspections at multiple stages, from the initial material inspection to the final product testing. Our quality control team uses advanced measurement tools and techniques to verify the dimensions, surface finish, and structural integrity of each part. By maintaining strict quality standards, we ensure that the cabinets we deliver are reliable, long-lasting, and compliant with industry regulations and safety requirements.

In conclusion, our sheet metal stamping service for computer and industrial control cabinets combines precision, durability, cost-effectiveness, flexibility, and stringent quality control. We are committed to providing our clients with high-quality cabinets that protect and enhance the performance of their electronic and control systems. As technology and industry continue to advance, we look forward to leveraging our expertise and innovation to meet the evolving needs of our clients in the computer and industrial sectors.